No products available yet

Stay tuned! More products will be shown here as they are added.

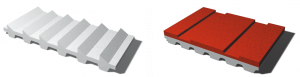

Firstly, BRECO® and Brecoflex® belts with or without a coating can be machined mechanically to perform specific functions.

Straps with a thicker back (type “DR”) allow to have a greater variety of machining. It should be noted, however, that thicker back straps are less flexible: they should be used with larger diameter pulleys than standard pulleys. Then, the flexibility can be increased by grooves or transverse slots.

The belts can also be machined by water jet. It is thus possible to obtain shapes and cuts of high precision for special applications.

|

Pitch |

T5 |

T10 – AT10 |

T20 – AT20 |

L |

H |

|

Thickness of the back mm) |

2,2 |

4,5 |

8 |

2,85 |

3,55 |

|

Max depth machining (mm) |

1,2 |

2,5 |

5 |

1,8 |

2,2 |

Milling the back in the width of the belt: |

|

|

|

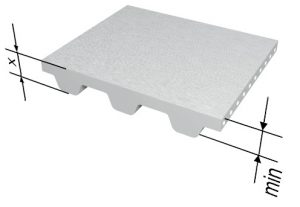

The transverse grooves increase the flexibility of the belt. Countersunk grooves, to the extent technically feasible, are also used for positioning or indexing. |

Milling the back in the length of the belt: |

|

|

|

Longitudinal milling offers different guiding solutions regardless of the belt pitch:

The depth of the groove X is to be rated from the back of the belt. |

Rectification of the back: |

|

|

|

The back of the BRECO® and Synchroflex® belts can be rectified. That of BRECOFLEX® belts is rectified to production. This operation is recommended for:

Attention: the total thickness X must respect a minimum thickness in order not to damage the cables. |

Edge grinding: |

|

|

|

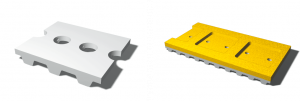

Edge grinding provides belts with tight width tolerances. This is particularly suitable for BRECO® belts guided by rails where rectified edges may be required. |

Deletion of teeth: |

|

|

|

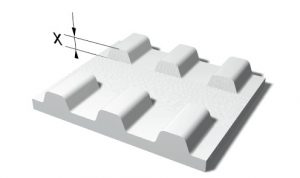

Groups of teeth or isolated teeth can be removed. The remaining teeth are then used to obtain accurate positioning. |

Milling of the teeth in the length of the belt: |

|

|

|

BRECO® belts with longitudinal tooth milling are often performed in combination with non-corded areas for vacuum transport. So we have many possibilities in this area. The machining depth X is calculated from the head of the tooth. |

Piercing: |

|

|

|

The belts with holes are made from belts with zones without cables and whose teeth have been machined in length. Moreover, they are used in the technique of vacuum transport in which we have a great experience. It is thus possible to transport parts such as very fragile films or metal plates of one square meter. |

Water jet machining: |

|

|

|

Different shapes can be made by waterjet cutting. Thus, this method allows to have clean machining, without burrs and very accurate. |

Stay tuned! More products will be shown here as they are added.