Chain drives are commonly used for transportation, linear motion, and power transmission. However, they generally require more maintenance, are less efficient, and have higher long-term operating costs.

While chains remain indispensable for certain highly demanding applications, timing belts are a more efficient alternative in many cases. Polyurethane timing belts are particularly notable for their precision, low noise levels, and reduced maintenance requirements, especially in systems requiring synchronized and repeatable motion.

Let's take a closer look at the main differences between chain drives and timing belts, as well as the factors to consider when choosing the one that best suits your needs.

Key points

- Both chain and timing belt drives transmit motion, but they rely on different technologies and materials.

- Chains are suitable for very harsh environments and high loads with significant shocks.

- Timing belts are ideal for applications requiring precision, quiet operation, and low maintenance.

- The choice depends in particular on the load, speed, environment, noise level, budget, and maintenance capabilities.

es capacités de maintenance.

What is the difference between a chain drive and a belt drive?

Chain and timing belt drives perform the same function: transmitting motion from a motor to a driven component. However, their designs differ, which affects their performance, uses, and long-term costs.

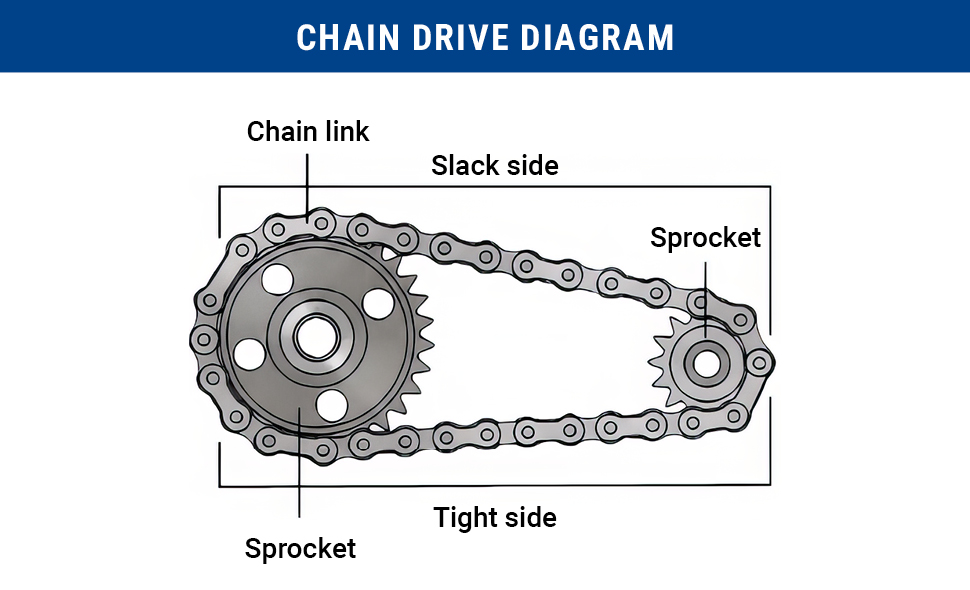

Chain drives

Made primarily of hardened or stainless steel, chains offer excellent mechanical strength. They are particularly suited to low-speed, high-torque applications or those subject to significant shock, such as in heavy industry or agriculture.

On the other hand, they require regular lubrication, frequent tension adjustments, and periodic replacement, which increases maintenance costs and downtime.

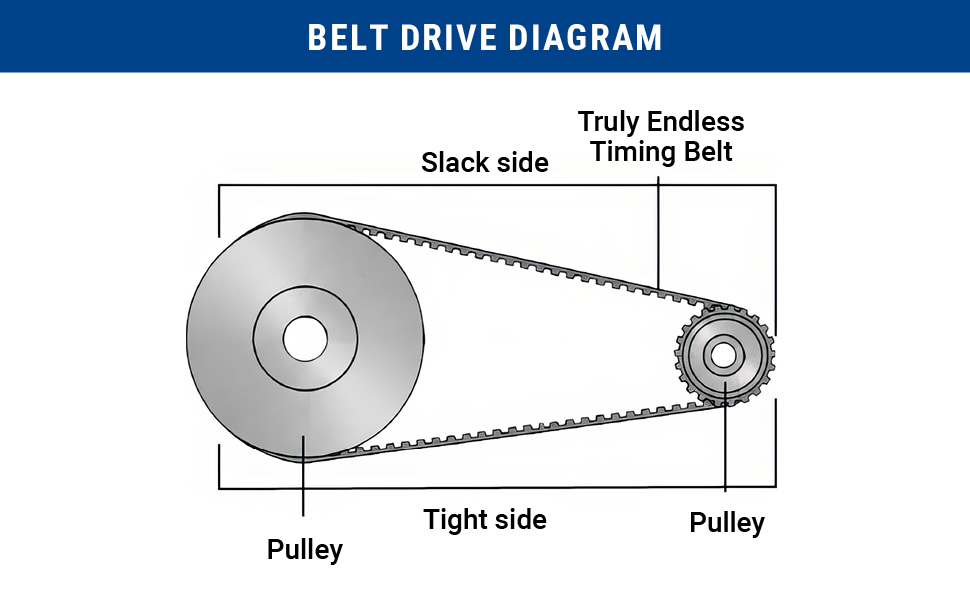

Timing belts

Timing belts, on the other hand, mesh with pulleys to transmit motion. Usually made of polyurethane reinforced with tension elements, they offer excellent dimensional stability and durability.

Unlike chains, they hardly stretch over time, ensuring precise and repeatable transmission. They are quieter, cleaner, and require little maintenance, which means they are generally less expensive than chains over their lifetime.

Comparison table between timing belts and chain drives

|

Element |

Timing belts |

Chain drives |

|

Material |

Polyurethane, neoprene (rubber) |

Hardened steel, stainless steel |

|

Lubrication required? |

No |

Yes |

|

Maintenance |

Minimal |

Extensive |

|

Upfront cost |

Moderate |

Lower |

|

Lifetime system costs |

Lower (reduced downtime/maintenance) |

Higher (ongoing maintenance requirements) |

|

Noise |

Low |

High |

|

Precision |

High (minimal elongation, no backlash) |

Moderate (experiences chain stretch) |

5 reasons to switch from chains to timing belts

1. Cleanliness, safety, and reduced maintenance

Timing belts require no lubrication, eliminating the risk of contamination and improving the safety and cleanliness of facilities. The absence of metal-to-metal contact also reduces noise and vibration.

2. Better return on investment

While chains may seem less expensive to purchase, their high maintenance, labor, and downtime requirements increase their cost over time. Timing belts, which are more durable and easier to maintain, offer a higher ROI.

3. Increased precision

Thanks to their design, timing belts maintain excellent precision over time. The meshing with the pulleys limits backlash and ensures reliable synchronization, even at high speeds.

4. Energy efficiency

Lighter than chains, timing belts generate less friction and put less stress on components, contributing to better energy efficiency and reduced electricity consumption.

5. High configuration flexibility

Binder Magnetic timing belts offer numerous customization options: materials, tensioning elements, coatings, cleats, machining, and specific designs according to application requirements.

When should you choose timing belts?

Timing belts are particularly suitable for applications requiring precision, repeatability, hygiene, and quiet operation, such as:

- automation and robotics,

- high-speed packaging lines,

- the food and medical sectors.

Their versatility allows them to meet a wide variety of requirements, from light handling to wide conveyors. You may see a 12 mm wide timing belt in the joint of a robotic arm, or a 150 mm wide belt transporting cartons in a manufacturing plant. It all depends on the requirements of the specific application.

Finding the right solution

Binder Magnetic will help you choose the most suitable solution for your application. With over 30 years of expertise in polyurethane timing belts, our technical team provides personalized, free support to optimize the precision and efficiency of your systems. Contact us to confirm the best choice for your application!